Case Study Technical Sheet

Client Company

Bel-Ray Corporation

Industry

Global Manufacturing and Distribution of High-Performance Lubricants and Fluids (Chemical / Industrial)

Main Challenge

Low inventory accuracy, poor lot traceability, and high inefficiency in picking operations.

Implemented Solution

invasWMS (Warehouse Management System)

Featured Interviewees

Rodrigo González Cataldo, National Logistics Manager

Valentín Oliva, Logistics Analyst

Ignacio Salinas, Logistics Analyst

The Scenario Before invasWMS: Bel-Ray’s Challenges

Bel-Ray, a leader in the production of lubricants for critical applications (from mining to motorsport), operated within a highly complex logistics environment. The handling of hazardous chemical products, multiple packaging formats (containers, drums, barrels), and the strict requirement for lot control created significant friction in operations:

Expiration Risk: Without strict automated control, there was a risk of shipping products nearing expiration—an unacceptable situation in their industry.

Chronic Inaccuracy: Inventory accuracy remained below 92%, forcing costly annual inventory shutdowns and generating shipment errors to customers.

Limited Productivity: Staff wasted time searching for products due to static location assignments and inefficient picking routes.

The Strategic Solution: invasWMS

The invasWMS team implemented a modular and highly configurable solution focused on Bel-Ray’s critical pain points:

1. Full Traceability Module (LPN & Lot Control)

The system was configured to enforce scanning of Lot Number and Expiration Date at every touchpoint (receiving, put-away, picking).

Value for Bel-Ray: Guaranteed FEFO (First Expired, First Out) compliance, eliminating the risk of shipping expired lubricants and ensuring quality audit compliance.

2. Dynamic Location Management

The system automatically directs high-rotation products to easily accessible zones.

Value for Bel-Ray: Significant improvement in vertical space utilization and increased dispatch speed.

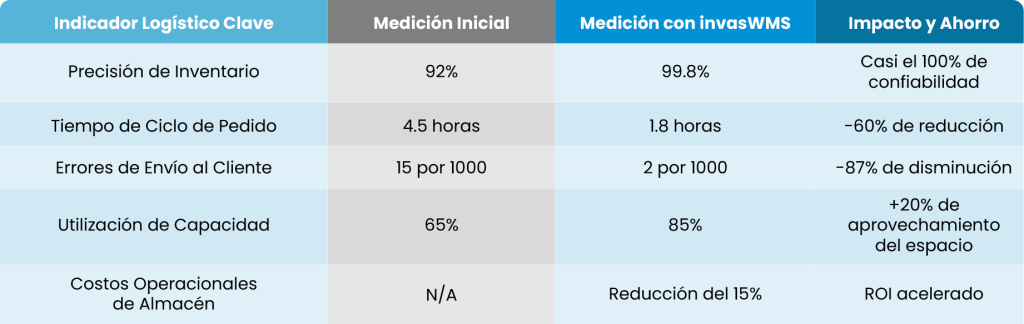

Measurable Results and High Impact

The implementation of invasWMS transformed Bel-Ray’s warehouse from a cost center into a customer service engine, delivering the following key results within the first 12 months:

“The implementation of invasWMS was not just a software upgrade; it was a transformation of our operational culture. We are no longer searching for products—we are shipping them. The accuracy and speed we have gained allow us to serve our customers better and have given us a competitive advantage in the high-performance lubricants market, where traceability is a necessity, not a luxury. The lot management system gives us the peace of mind our industry demands.”

— Rodrigo González Cataldo, Head of Logistics Chile, Bel-Ray CorporationThe success of Bel-Ray Corporation is a tangible example of how invasWMS delivers the operational intelligence required for companies with strict quality and traceability demands to raise their standards. invasWMS is the partner that helps turn your warehouse into a competitive advantage.