Executive Summary

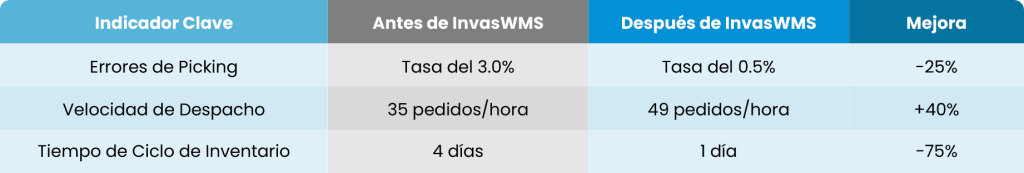

Provaltec, a leading company in the distribution of industrial valves and water filtration equipment—among many other solutions—was facing growing challenges in inventory management and dispatch speed, directly impacting customer satisfaction and operating costs. After implementing InvasWMS, the company achieved a 25% reduction in picking errors and a 40% increase in order processing speed, consolidating its position as a benchmark in logistics efficiency.

The Challenge: Growth and Logistics Complexity

With a constantly expanding product portfolio and a sustained increase in order volume, Provaltec encountered a bottleneck in its warehouse operations:

Low Accuracy: Reliance on manual processes and spreadsheets resulted in a high rate of picking and packing errors, leading to costly returns and a deterioration in customer experience.

Operational Inefficiency: The lack of real-time visibility into the exact location of inventory slowed down the picking process and the inventory counting cycle.

Cost of Poor Quality: Logistics errors generated additional costs due to reshipments, overtime labor, and the need for excessive safety stock.

The Solution: Strategic Implementation of InvasWMS

Provaltec selected InvasWMS for its robustness, scalability, and seamless integration with its existing ERP. The implementation focused on the following key areas:

- Intelligent Location Management: A dynamic slotting system was implemented, optimizing the placement of high-rotation products to minimize operators’ travel paths.

- Mobile Device–Guided Picking: Paper lists were eliminated. Picking staff now use mobile devices with scanners, ensuring SKU and quantity validation at the pick point and driving accuracy to near-100% levels.

- Cycle Counting: The costly and disruptive annual inventory count was replaced with a continuous, automated cycle counting process, maintaining constant inventory accuracy without halting operations.

- Full Integration and Traceability: InvasWMS was seamlessly integrated with Provaltec’s systems, providing full visibility into the status of every order and SKU from receiving through final dispatch.

The Solution: A Partner That Clearly Stood Out

- Company: Dräger Chile

- Interviewee: Pablo Angulo Lastra, Operations, Logistics and Supply Chain Manager

- Industry: Medical and safety technolog.

- Profile: Dräger is a global market leader with more than 80 years of history, specialized in “Technology for Life.” It operates in two main divisions: Medical, which provides critical equipment for operating rooms and patients (anesthesia machines, ventilators, incubators), and Safety, which develops respiratory protection equipment for mining, firefighters, and mine rescue shelters.

The Results: Transformation and Competitive Advantage

The adoption of InvasWMS delivered a transformative impact on Provaltec’s operations, allowing the company to focus its resources on business growth:

Unprecedented Accuracy:

The sharp 25% reduction in picking errors led to an immediate decrease in error-related returns and a tangible improvement in customer trust.

Increased Productivity:

By optimizing routes and guiding staff, Provaltec was able to process 40% more orders per hour, handling demand increases without proportionally expanding warehouse headcount.

Cost Reduction:

Time spent on physical inventory counting was reduced by 75% (from 4 days to just 1 day), freeing staff for value-added tasks and optimizing working capital through more accurate inventory.

“The implementation of InvasWMS was a game changer for Provaltec. Not only did we solve our accuracy and speed issues, but we also gained a strategic tool that allows us to grow with confidence. Today we can promise and deliver lead times that our competitors simply can’t match. invasWMS is our engine of competitive advantage.”

— Logistics Operations Manager, Provaltec